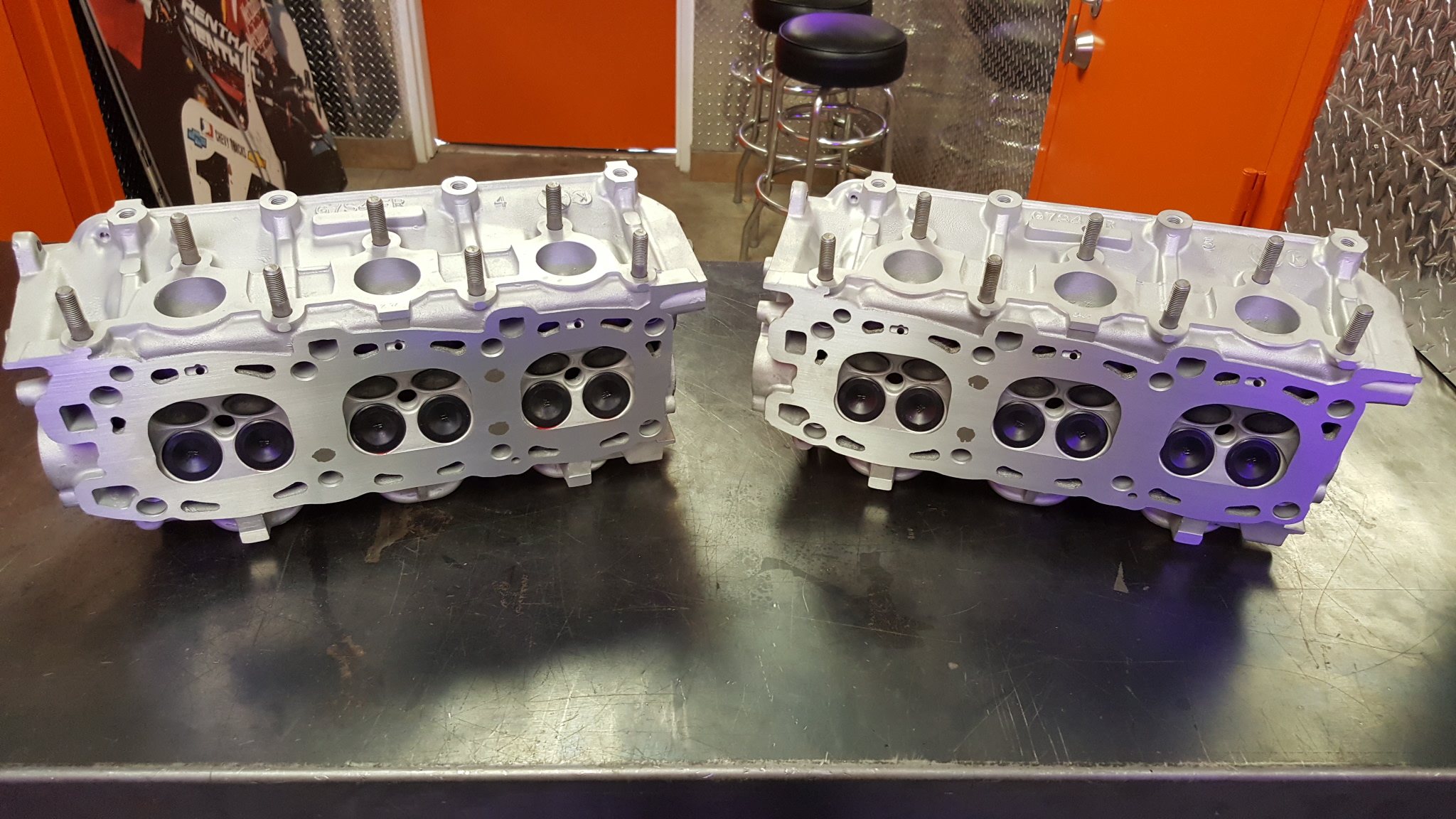

This is a set of Mitsubishi Montero 3.0 V6 aluminum cylinder heads that we performed a three angle valve job and surface to. These heads are SOHC which stands for single overhead cam. This means that there is one camshaft on each cylinder head. Each cylinder has 4 valves so this engine is referred to as a SOHC 24-valve V6 engine. The heads are first disassembled, hot tanked, dye checked for cracks, and then pressure tested to make sure there aren’t any leaks. Once it is determined that there aren’t any leaks or cracks the heads are mounted in our Tobin Arp seat and guide machine so we can machine the valve seats which is the heart of the valve job. After the seats have been machined the heads then go into either our AMC surfacer surfacing machine or our Winona Van Norman Headmaster or Blockmaster machines to get their surfaces milled flat and square. All the valves are also cleaned, measured, inspected, and then ground on our Sioux valve grinder. The heads are then mocked up with all their valves installed so we can check, measure, and set or adjust the installed valve stem heights. Once the valve stem heights are all set we install the new positive viton valve stem seals and then assemble the cylinder heads. The last thing we do is a vacuum test on each individual intake and exhaust port to make sure all the valves are seating and sealed on the valve seats for a 100% seal. For all of your machine shop, engine & cylinder head rebuilding, and fabrication needs please give us a call or come in and stop by. Motor Mission Machine & Radiator 5435 Desert Point Dr. Las Vegas, Nv. 89118 Ph: (702) 649-2366 or (702) 649-0648 Fax: (702) 649-4133 www.MotorMission.com