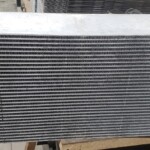

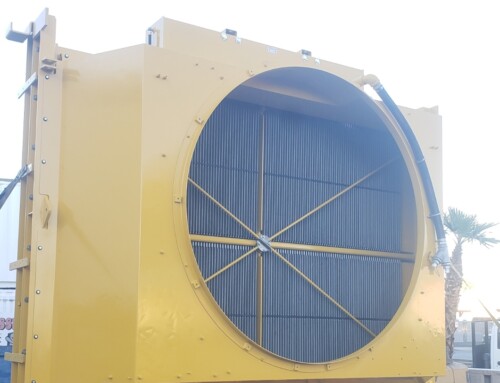

Here’s some pics of an aluminum radiator we had in for a Grove RT600E crane that was leaking in the tubes of the core from internal plugging, or fouling. The build-up inside the tubes allowed corrosion to take place which ate the tubes up internally causing leaks in the tubes of the core. We cut the tanks (end caps) off the bad core, machined them to size & then tig welded them onto a new heavy duty bar-and-plate radiator core. The radiator pressure tested good & it is now as good, or better, than new for much less than a new radiator from the manufacturer. Recoring the radiator also got the machine back up & running much quicker than ordering a new radiator from the OEM as it was 120 plus days out.

5435 Desert Point Dr. Las Vegas, Nv. 89118 Ph: (702) 649-2366 or (702) 649-0648 Fax: (702) 649-4133 www.MotorMission.com Facebook.com/MotorMission

5435 Desert Point Dr. Las Vegas, Nv. 89118 Ph: (702) 649-2366 or (702) 649-0648 Fax: (702) 649-4133 www.MotorMission.com Facebook.com/MotorMission