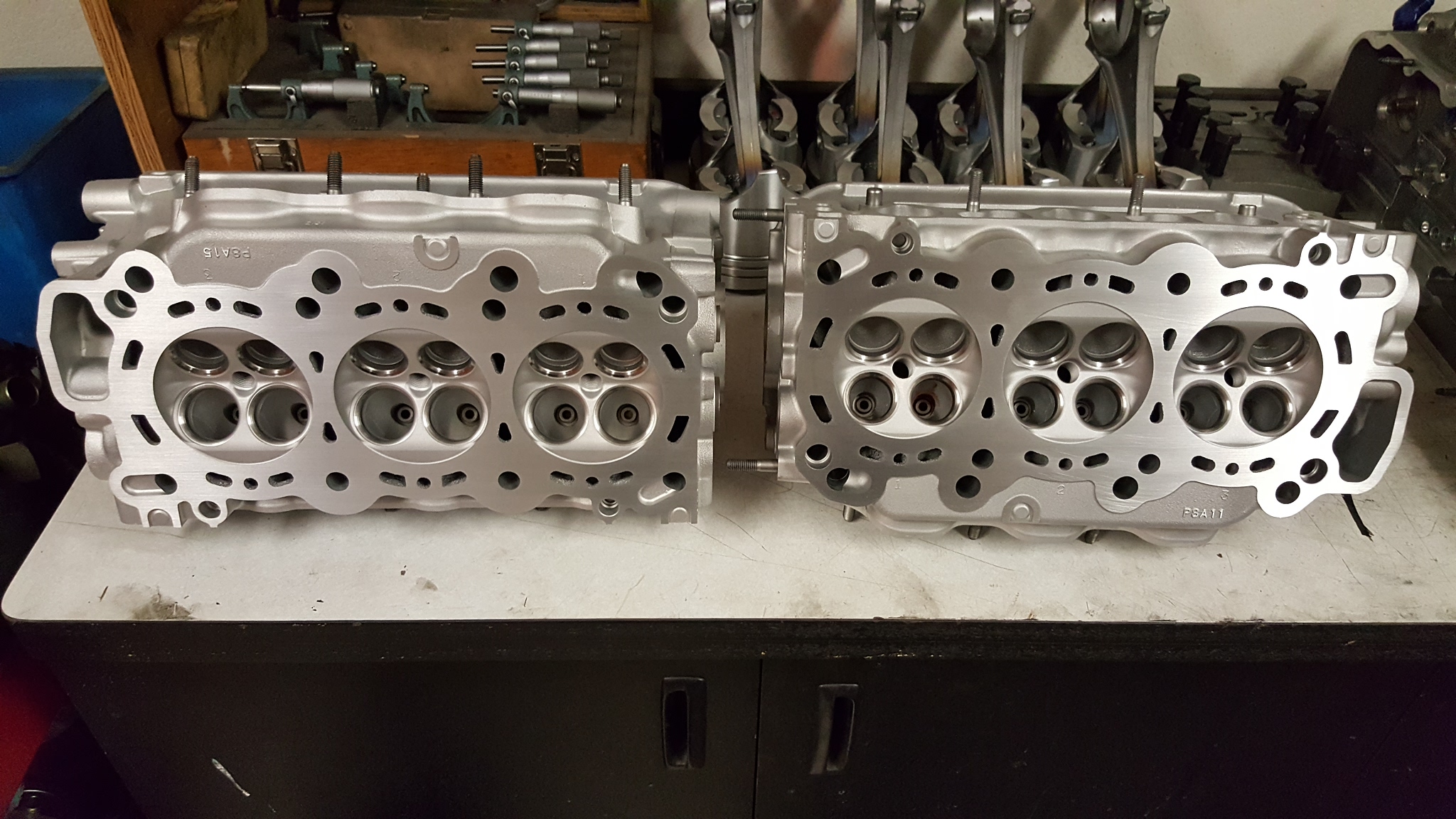

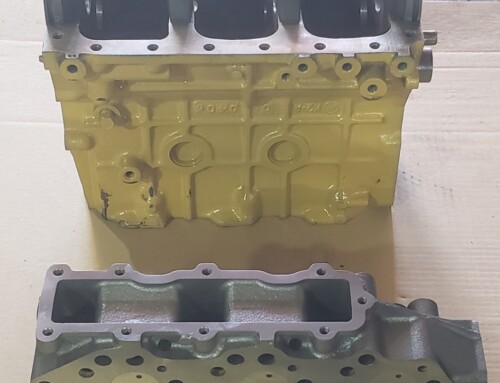

This is a set of aluminum Honda V6 cylinder heads that came in for rebuilding. We completely disassembled the cylinder heads so we could hot tank and then sandblast them completely clean inside and out. We then mounted the cylinder heads in our pressure tester testing machine so we could pressure test them to make sure they have no leaks. After confirming that the heads aren’t cracked or leaking we then mounted them in our Tobin Arp seat and guide machine so we could cut and machine the three angles into the valve seats with our Sunnen 3-angle seat cutting tools. After the valve job was complete we then mounted the cylinder heads onto our AMC surfacer surface grinding machine so we could surface and mill the decks of both heads flat and square. The intake and exhaust valves were then chucked up into our Sioux valve grinder so we could grind the faces of the valves true and round. Once all the machine work was completed we assembled the heads with some new positive viton valve stem seals and then we vacuum tested each individual intake and exhaust port to make sure the valves are seating 100% on their respective valve seats so that they will yield a perfect compression test once installed back on the engine. Motor Mission Machine & Radiator 5435 Desert Point Dr. Las Vegas, Nv. 89118 Ph: (702) 649-2366 or (702) 649-0648 Fax: (702) 649-4133 www.MotorMission.com