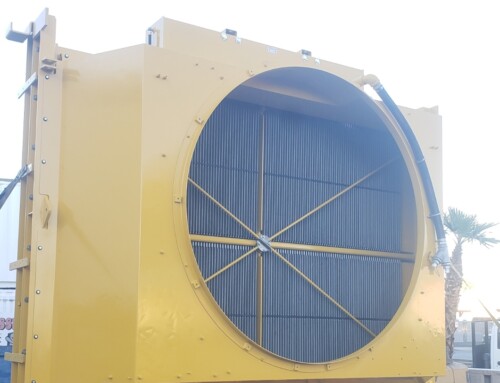

Here’s some pics of a large aluminum charge air cooler we recored for a Caterpillar 6060 Hydraulic Shovel. The intercooler is so large that it is made up of four individual bar-and-plate cores which are all tig welded together to make one complete unit. We recore a fair amount of aluminum coolers for both liquid as well as air cooling. The tanks are thick heavy duty extrusions which we cut off of the original cores that are bad. We then machine the tanks flat, square & to the size we need for tig welding to a new heavy duty core. After all the cleaning & prepping is done the tanks are tack welded to the core in a jig. Once everything is all set & the cooler, or radiator, meets the required dimensions we begin pre-heating the tanks & core before complete tig welding. After all the welding is done we put the cooler, or radiator, through a rigorous pressure test to ensure there are absolutely zero leaks.

5435 Desert Point Dr. Las Vegas, Nv. 89118 Ph: (702) 649-2366 or (702) 649-0648 Fax: (702) 649-4133 www.MotorMission.com Facebook.com/MotorMission

5435 Desert Point Dr. Las Vegas, Nv. 89118 Ph: (702) 649-2366 or (702) 649-0648 Fax: (702) 649-4133 www.MotorMission.com Facebook.com/MotorMission