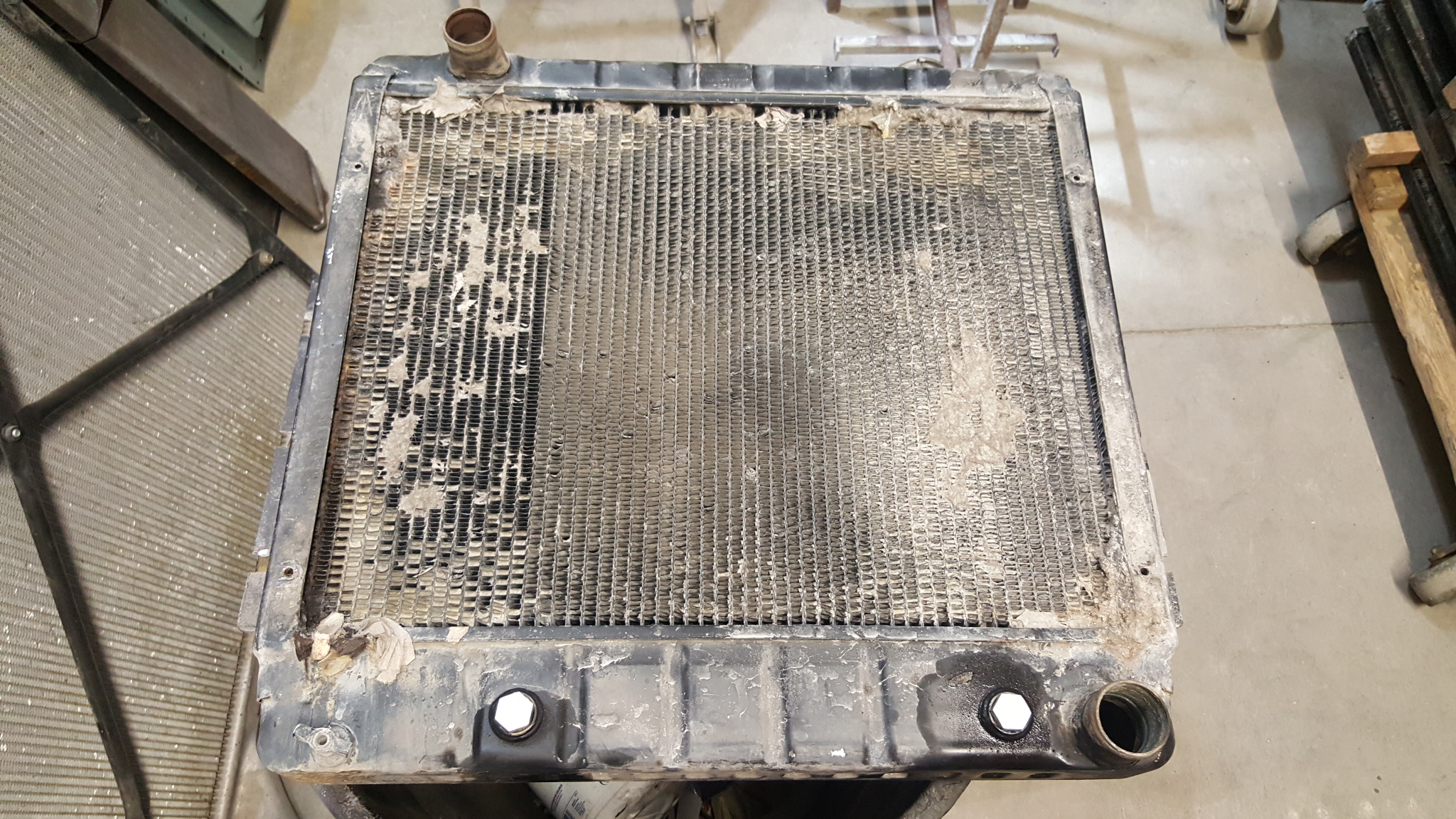

This is an industrial all metal copper and brass heavy duty high efficiency radiator for a Komatsu forklift. We get a lot of agricultural style radiators in for agriculture equipment that look like this radiator. Sometimes we will just do a rod and repair in which we melt the solder out of the seams so we can remove the radiator tanks. Some people refer to the radiator tanks as radiator end caps. Once we get the brass radiator tanks removed from the core we then boil the core in the hot tank, boil out tank, and ultrasonic cleaning tank before actually running a rod down and through every single tube. Some people refer to this as coring the radiator but we call it a rod and repair. The repair is soldering any leaks or damage / dents that the radiator core and tanks might have. This particular customer has requested as much cooling as possible so we are not going to bother with performing the rod and repair. We are going to recore / re-core / re-coring / recoring this radiator. We will build / manufacture a high efficiency 4 row core, thermal clean & blast the radiator tanks, and run the headers on the new core. Running the headers means running / melting solder around each tube / core where they go up and through the header plates. Once the headers are run, we will then tin up the tanks, clamp the tanks to the headers of the new core, and then solder the seams. Once the radiator is all assemble we will submerge the complete radiator assembly in our test tank to perform the pressure test. After the pressure test is passed and completed we will do a final clean, flush, and prep the radiator before giving it a fresh paint job. Motor Mission Machine & Radiator 5435 Desert Point Dr. Las Vegas, Nv. 89118 Phone: (702) 649-2366 or (702) 649-0648 Fax: (702) 649-4133 www.MotorMission.com